CTEC 300U Tape Edge Machine

How to Choose A Perfect Mattress Tape Edge Machine for Making Perfect Mattress

A tape edge machine is a crucial pillar in a mattress manufacturing unit as it automates the process of sewing the fabric cover edges, ensuring a neat, durable, and consistent finish. This machinery enhances productivity, maintains high-quality standards, and reduces manual labor, which is essential for efficient mass production of mattresses. Its precision and speed are vital for meeting market demand and ensuring the durability and aesthetic appeal of finished mattresses.

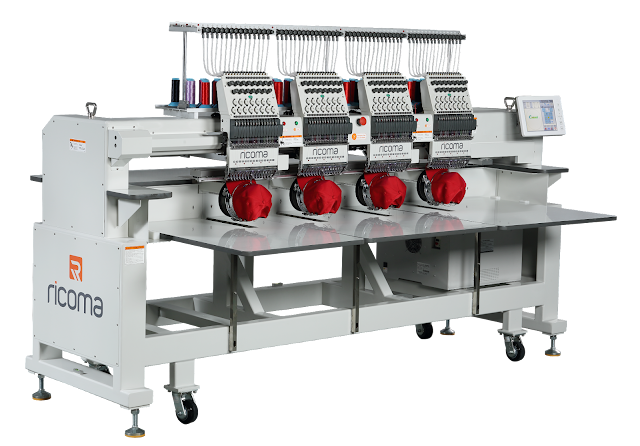

A perfect shape machine combined with high-quality, strengthened parts is essential for producing mattresses of superior quality, as it ensures precise shaping, uniformity, and durability. The shape machine guarantees that each mattress conforms to the desired contours and specifications, while robust components enhance the machine’s longevity and performance, resulting in consistent, long-lasting mattresses. Together, these elements contribute to the overall comfort, durability, and customer satisfaction, making them vital for a reputable mattress manufacturing process.

The machine should be designed for complete dismantling when repairs are needed to facilitate easy maintenance, reduce downtime, and ensure safety. A machine that can be fully disassembled allows for thorough inspection, replacement of worn parts, and efficient troubleshooting, ultimately maintaining optimal performance and extending its lifespan. This modular approach simplifies repairs and minimizes disruptions to the manufacturing process, ensuring continuous productivity and high-quality output.

A machine that can be easily described and simplified for operation is designed with user-friendly controls, clear instructions, and intuitive functionality, making it accessible even for operators with minimal technical experience. Simplifying the machine involves reducing complexity, using straightforward interfaces, and providing visual or digital guides to ensure safe and efficient operation. This approach enhances productivity, minimizes errors, and promotes safety, thereby enabling smooth operation and maintenance of the machine.

A mattress making machine designed for producing different types of mattresses is a versatile and customizable equipment that can handle various materials, sizes, and designs to create a wide range of mattress varieties such as foam, spring, latex, or hybrid models. These machines typically feature adjustable settings for dimensions, firmness, and layer configurations, allowing manufacturers to efficiently produce diverse mattress styles to meet market demands. Their user-friendly interfaces and modular components facilitate easy operation, quick changeovers, and maintenance, enabling manufacturers to diversify their product offerings while maintaining high quality and productivity.

To produce different styles of mattresses with high quality and durability, a heavy-duty and robust mattress making machine is essential, featuring reinforced construction, high-grade materials, and powerful components that can handle various materials like foam, springs, and latex with ease. Such machines should be equipped with adjustable settings for different mattress sizes, thicknesses, and designs, ensuring versatility while maintaining strength and stability during production. Investing in a durable, well-built machine ensures long-term performance, minimizes downtime, and consistently delivers high-quality mattresses across different styles, meeting industry standards and customer expectations.

For more information and purchase please write us on vardhmaanautomation@gmail.com

Company: Vardhmaan Automation

Call Us On: +91-9711188817

Comments